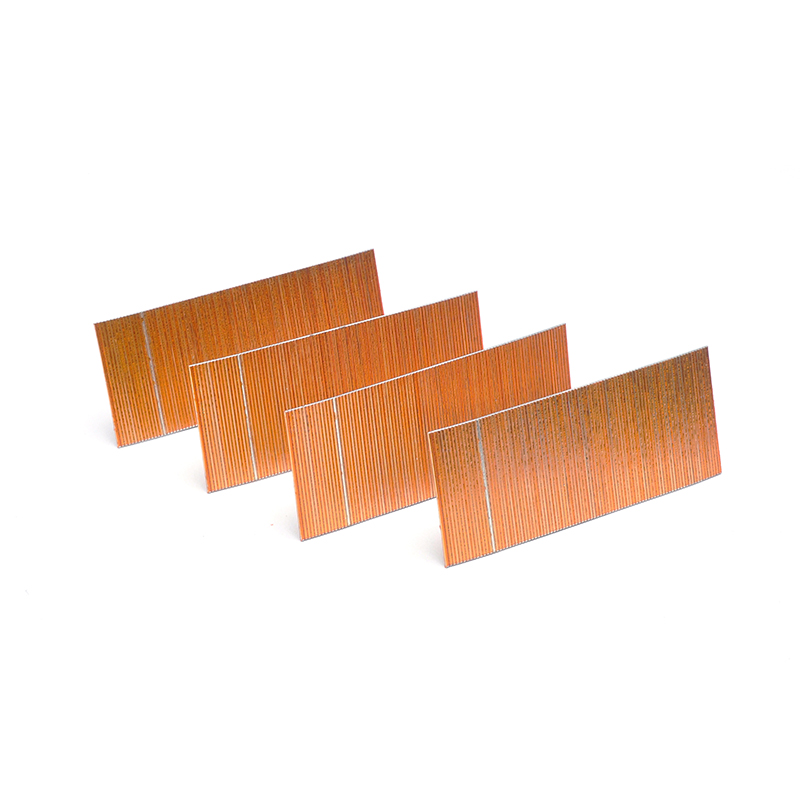

Staple Wire Band has become a crucial raw material component in manufacturing staples, brads, and pins. For buyers managing procurement, production, and quality, understanding its performance and specifications is essential.

Staple Wire Band Efficiency in Production

A well-suited Staple Wire Band can significantly reduce machine downtime and scrap rates. Bands with tensile strength in the range of 540–1400 N/mm² and widths between 0.41–1.37 mm allow production lines to run more smoothly. Switching from lower strength bands below 600 N/mm² to higher strength grades above 900 N/mm² can reduce rejection rates by around 15 %,causing fewer machine jams and more consistent output. Even small improvements in wire uniformity and surface coating can increase line speed and reduce energy consumption. For buyers, this translates into tangible efficiency gains, smoother operations, and measurable improvements in overall production output.

Staple Wire Band Quality & Buyer Satisfaction

Quality is the top priority for buyers. Inconsistent or weaker bands often cause jamming, stoppages, or product defects, affecting overall satisfaction. High-quality bands typically feature galvanised or copper-coated surfaces, consistent flattening degrees of 0.70–1.80 mm, and reliable spool packaging. Buyers prioritizing these attributes often experience fewer disruptions, higher line reliability, and better end-product quality. Positive feedback frequently highlights ease of use, long-lasting performance, and reduced machine maintenance. Uniform bands also improve staple alignment, resulting in cleaner, more precise stapling, which directly influences customer satisfaction in downstream applications.

Staple Wire Band Specification Comparisons

Comparing specifications helps buyers match bands to their specific applications:

- Tensile strength: 540–750 N/mm² for copper-coated bands versus 950–1050 N/mm² for galvanised heavy-duty options.

- Width × thickness: ranges from 0.65 × 0.95 mm for standard applications to 1.37 × 1.59 mm for heavy-duty use.

- Flattening degree: 0.70–1.80 mm, ensuring proper fit in stapling machines.

Selecting the correct specification prevents line stoppages, reduces cost from overspending on over-specified bands, and ensures production quality aligns with expectations. Careful attention to wire uniformity and spool tension can also prevent staple misfeeds and machine wear.

Staple Wire Band Market and Supply Considerations

Buyers must also assess market and supply factors. Heavy import-dependence in certain regions can influence availability and pricing. Trade regulations or tariffs on certain raw materials may impact cost or delivery timelines. Evaluating supply-chain stability, times, and sourcing origin is critical. Planning ahead allows buyers to mitigate risk, maintain consistent production flow, and adjust procurement strategies according to seasonal demand or market fluctuations.

Staple Wire Band Buying Checklist

When preparing a purchase order, buyers should consider:

- Tensile strength suitable for production needs, especially for heavy-duty applications.

- Surface coating type: galvanised, copper-coated, or stainless steel depending on environment.

- Flattening degree and width/thickness to ensure compatibility with machines.

- Spool packaging to avoid deformation during transport.

- Supply-chain stability, times, and potential trade restrictions.

- Additional factors such as wire straightness, uniformity, and coating adhesion to improve performance consistency.

In summary, Staple Wire Band is far more than a basic raw material. Selecting the right band influences not only production efficiency and line reliability but also the overall quality of finished products. Buyers who carefully assess specifications, surface coating, tensile strength, and supply-chain stability can achieve smoother manufacturing operations, lower scrap and waste rates, more consistent staple performance, and greater long-term satisfaction. Attention to detail in procurement decisions ensures that every production cycle runs reliably, minimizes costly interruptions, and delivers consistent results that meet both operational and customer expectations.

English

English русский

русский 中文简体

中文简体 عربى

عربى

Quick Links

Quick Links